Your Cart is Empty

Thank you for using our Modern Fuel Bolt Action Mechanical Pencil. It is a precision writing instrument that has been manufactured to the highest quality standards and we hope that it will provide you many years of optimal use. Your Modern Fuel writing instrument is unique in that its cone and body will only ever match with each other due to the custom-finish process used during the manufacturing process.

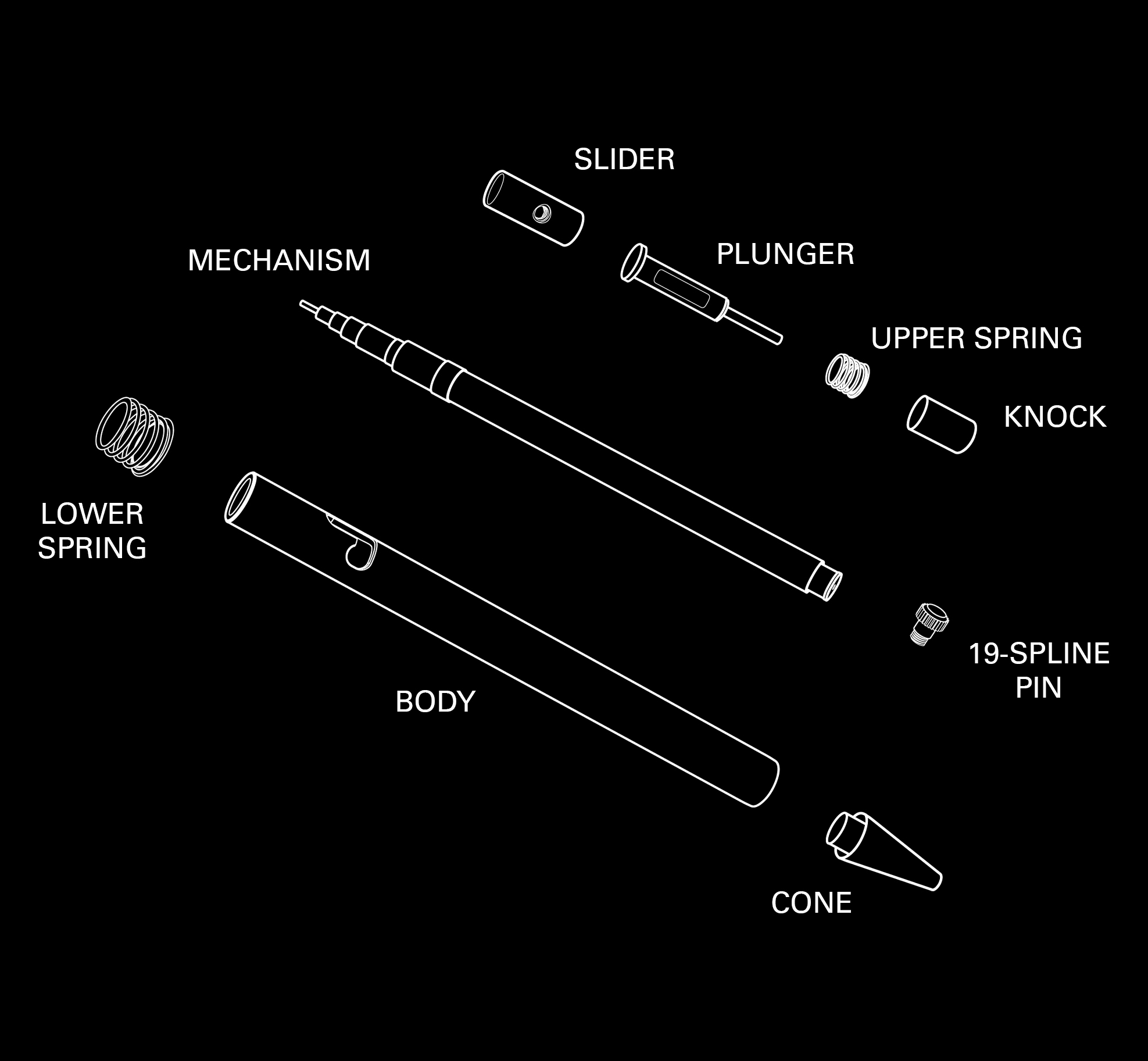

For your convenience, we have included written instructions with diagrams below, as well as videos showing how to do the same procedures. Most issues with our writing instruments can be solved quickly using the steps outlined below. Rarely, a manufacturing defect may present itself and necessitate a warranty replacement. See the information below for submitting a request for warranty service.

1. Unscrew the cone of your pencil and remove the mechanism, using caution not to lose the spring.

2. Remove the cap from the mechanism and load with the proper size graphite sticks, then replace the cap

3. Re-insert the mechanism and spring, and then screw the cone back into place

The pencil mechanisms can be identified by looking at the cone and reviewing the number of lines. For the bolt action mechanical pencil, the identifying markings are as follows:

3 lines - 0.9mm

2 lines - 0.7mm

1 line - 0.5mm

No line - 0.3mm

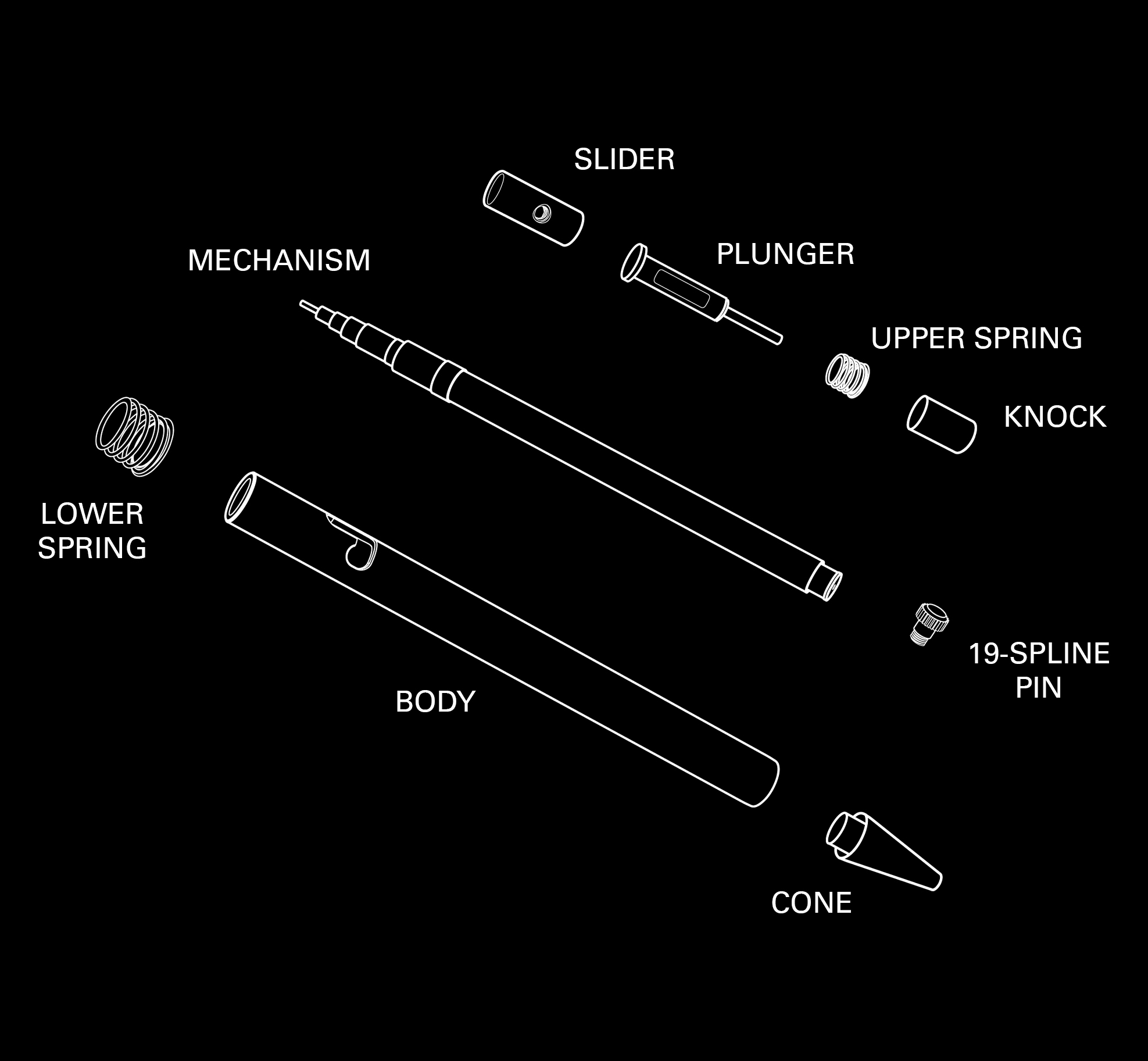

The knock and assembly can be disassembled for cleaning as necessary using the following steps:

1. Unscrew the 19-spline pin. You may use the included wrench as necessary to complete this step.

2. Remove the slider, plunger, spring, and knock assembly

3. With the assembly outside the body of the pencil, rotate the knock to align the flat spot of the plunger in the slider hole for the pin and re-insert the pin. This will prevent the plunger from rotating while you unscrew the knock.

4. Unscrew the knock of the pencil from the plunger, being careful not to lose the spring.

5. Unscrew the pin from the slider and remove the plunger.

6. Follow these steps in reverse for reassembly.

The pencil mechanism may occasionally jam and require cleaning to get working again. Please follow these steps to clean the mechanism:

1. The pencil mechanism may occasionally jam and require cleaning to get working again. Please follow these steps to clean the mechanism:

2. Remove any spare graphite from the mechanism by removing the cap and dumping it out.

3. Unscrew the cone of the mechanism.

4. Using a spare piece of graphite, clear out the graphite support tube. It is recommended to also use compressed air to blow out the mechanism cone. Use caution to protect your eyes during this process.

5. Check the clutch area to ensure no pieces are stuck. Remove graphite debris / dust as necessary.

6. Reassemble in reverse order.

To troubleshoot graphite that will not advance, please start by ensuring that extra pieces of graphite are inside the tube of the mechanism. Then, try shaking your pencil several times while clicking the knock to advance the graphite at the same time.

If you are still not successful, follow the steps above to clean the pencil mechanism and repeat the steps shown in the previous paragraph.

Raw copper and bronze will develop a natural patina over time. Most people appreciate this rustic look, however if you wish to restore your pencil to its original condition you may with the following steps.

Completely disassemble your pencil

Mix lemon juice or vinegar with salt, and use a soft cloth to rub the mixture on all surfaces you wish to clean

Using a dry portion of the cloth, wipe down all surfaces to dry them

Repeat as necessary to bring back the original shine

Short top in soft fabric with a square neckline and draped bodice. Long sleeves with narrow elastic at shoulders and cuffs. Lined bodice.

Thank you for using our Modern Fuel Bolt Action Mechanical Pencil. It is a precision writing instrument that has been manufactured to the highest quality standards and we hope that it will provide you many years of optimal use. Your Modern Fuel writing instrument is unique in that its cone and body will only ever match with each other due to the custom-finish process used during the manufacturing process.

For your convenience, we have included written instructions with diagrams below, as well as videos showing how to do the same procedures. Most issues with our writing instruments can be solved quickly using the steps outlined below. Rarely, a manufacturing defect may present itself and necessitate a warranty replacement. See the information below for submitting a request for warranty service.

1. Unscrew the cone of your pencil and remove the mechanism, using caution not to lose the spring.

2. Remove the cap from the mechanism and load with the proper size graphite sticks, then replace the cap

3. Re-insert the mechanism and spring, and then screw the cone back into place

The pencil mechanisms can be identified by looking at the cone and reviewing the number of lines. For the bolt action mechanical pencil, the identifying markings are as follows:

3 lines - 0.9mm

2 lines - 0.7mm

1 line - 0.5mm

No line - 0.3mm

The knock and assembly can be disassembled for cleaning as necessary using the following steps:

1. Unscrew the 19-spline pin. You may use the included wrench as necessary to complete this step.

2. Remove the slider, plunger, spring, and knock assembly

3. With the assembly outside the body of the pencil, rotate the knock to align the flat spot of the plunger in the slider hole for the pin and re-insert the pin. This will prevent the plunger from rotating while you unscrew the knock.

4. Unscrew the knock of the pencil from the plunger, being careful not to lose the spring.

5. Unscrew the pin from the slider and remove the plunger.

6. Follow these steps in reverse for reassembly.

The pencil mechanism may occasionally jam and require cleaning to get working again. Please follow these steps to clean the mechanism:

1. The pencil mechanism may occasionally jam and require cleaning to get working again. Please follow these steps to clean the mechanism:

2. Remove any spare graphite from the mechanism by removing the cap and dumping it out.

3. Unscrew the cone of the mechanism.

4. Using a spare piece of graphite, clear out the graphite support tube. It is recommended to also use compressed air to blow out the mechanism cone. Use caution to protect your eyes during this process.

5. Check the clutch area to ensure no pieces are stuck. Remove graphite debris / dust as necessary.

6. Reassemble in reverse order.

To troubleshoot graphite that will not advance, please start by ensuring that extra pieces of graphite are inside the tube of the mechanism. Then, try shaking your pencil several times while clicking the knock to advance the graphite at the same time.

If you are still not successful, follow the steps above to clean the pencil mechanism and repeat the steps shown in the previous paragraph.

Raw copper and bronze will develop a natural patina over time. Most people appreciate this rustic look, however if you wish to restore your pencil to its original condition you may with the following steps.